Recently, the intelligent automatic steel bar rolling production line developed and mass produced by our company has won the Beijing new technology and new product (service) certificate.

The certificate is certified and issued by Beijing Municipal Commission of science and technology. It is a product (service) with advanced technology, clear property rights, reliable quality and broad market prospect obtained by enterprises, universities, scientific research institutes and various social organizations through original innovation, integrated innovation and introduction, digestion, absorption and re innovation.

Being able to win this honor represents that the company’s intelligent full-automatic steel bar rolling production line has made obvious achievements in the field of steel bar engineering industrialization and the trend of energy conservation and environmental protection in the construction industry, and has been widely recognized by all sectors of the society!

This award means that the products will play a role in promoting air pollution prevention, sewage treatment, waste treatment, intelligent transportation, urban safe operation and emergency rescue, green building, housing industrialization and new rural construction. Recognized new technologies and products (services) can enjoy policy support such as government procurement, promotion and application.

Energy conservation and environmental protection are urgent

Fully implement the spirit of the 19th CPC National Congress and the second and third plenary sessions of the 19th CPC Central Committee, earnestly implement the decisions and arrangements of the CPC Central Committee and the State Council and the requirements of the national ecological and environmental protection conference, take the construction of ecological civilization as the guide, focus on the treatment of fine particulate matter (PM2.5), take intensive treatment as the means, CO governance as the basis and the rule of law as the guarantee, and focus on diesel trucks, dust In key prevention and control areas such as VOC Control, optimize and adjust the transportation structure, industrial structure, energy structure and land use structure, strengthen regional joint prevention and control, strive to strengthen urban fine management, comprehensively promote green development, resolutely win the blue sky defense war, and provide strong support for building a world-class harmonious and livable city.

By 2020, the improvement target of ambient air quality in this area will be further improved based on the target of the 13th five year plan, the concentration of PM2.5 will be significantly reduced, the number of days of heavy pollution will be significantly reduced, the ambient air quality will be significantly improved, and the citizens’ blue sky happiness will be significantly enhanced. Significantly reduce the total emission of major air pollutants, cooperate to reduce greenhouse gas emissions, and reduce nitrogen oxides and volatile organic compounds in the region by more than 30% compared with 2015; The ratio of heavily polluted days decreased by more than 25% compared with 2015. By 2020, the average concentration of PM2.5 in our region will be controlled at about 49 μ g / m3.

Strengthen construction dust control. All towns and streets are responsible for organizing various construction sites to comprehensively promote green construction, and strictly implement the dust control requirements of “six hundred percent” and “Three Guarantees in front of the door” for enclosure around the construction site, material stacking and covering, wet operation of earthwork excavation, pavement hardening, cleaning of incoming and outgoing vehicles, closed transportation of residue vehicles;

Low consumption and high efficiency, made in China

The full-automatic steel bar rolling production line developed and produced by our company can well solve this pain point problem, reduce energy consumption by greatly improving processing efficiency, and fully avoid the waste of human resources, land resources and energy consumption resources.

▲ High efficiency: process a 12m steel bar in 12 seconds, with a maximum processing capacity of 240 tons per shift. Only 2 people are required to override the whole line, which is 3-4 times the capacity of the conventional steel bar thread processing production line!

Mechanical connection technology of WL double screw sleeve reinforcement

On the other hand, WL double screw sleeve reinforcement mechanical connection technology is selected in the project, and the reinforcement component construction method is adopted to prefabricate the workpiece in advance, which will achieve better construction effect.

Taking the actual situation as an example, in the implementation of Humen No. 2 bridge and deep middle channel project, the construction unit has obtained the preliminary conclusion that the reinforcement component construction will shorten the construction time of reinforcement works on the working face by about 70% and the on-site construction personnel by about 70%. This not only solves the problems of pollution, dust and progress on the construction site, but also greatly shortens the construction period!

The intelligent automatic steel bar rolling production line is a revolution in the field of steel bar engineering industrialization. It truly completes the mission of low energy consumption, high efficiency, less manpower and less land occupation entrusted by the times. At the same time, this product not only makes you get twice the result with half the effort in terms of processing efficiency, but also achieves the industry-leading level in reinforcement processing accuracy!

▲ Full function: it integrates the functions of steel bar sawing, high-speed rib stripping, thread rolling, end leveling, etc. the same processing capacity means less workshop operation!

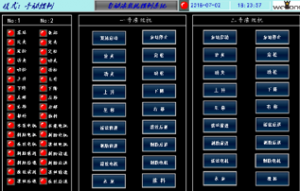

Main module functions

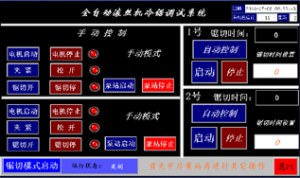

The informatization and intelligent management of this product will be reflected in the following modules:

Production line control center command module

- Prepare the equipment before the production shift according to the prompts on the system interface;

- According to the project and the company’s information management system, issue order instructions to the production line, and the system automatically generates daily processing plan and arranges production side by side;

- Manually adjust the position of the equipment according to the length of the reinforcement to be processed according to the production order;

- The operator of the production line manually adjusts the processing specifications of the thread rolling head and replaces the thread rolling wheels of corresponding specifications according to the instructions of the system interface;

- Start processing after being ready and receiving the machinable instruction;

- The system automatically generates production statistics reports.

Reinforcement sawing processing module

- The milling process is adopted, and the machined end face is flat, which fully meets the deformation performance requirements of the connecting joint;

- Milling processing has low noise, no dust pollution and meets the requirements of environmental protection;

- The efficiency of steel bar sawing is higher than that of wire rolling;

- The sawing length error shall be controlled within ≤± 1.0 mm,

- Reinforcement sizing measurement adopts automatic mode.

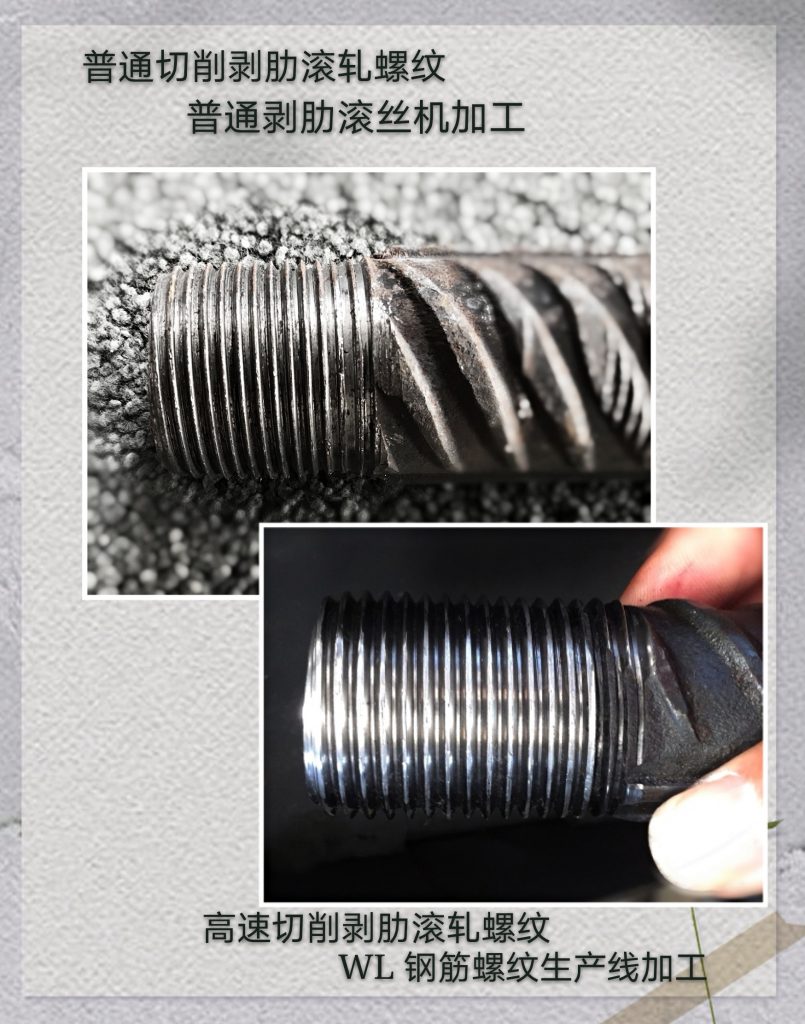

Reinforcement thread rolling processing module

- Thread rolling adopts two processes: rib stripping rolling and shaping direct rolling, and the production line device is configured according to the needs of customers;

- Rib stripping or shaping and thread rolling are divided into two process links and two sets of devices, which is conducive to improving the production and processing efficiency;

- Manually assisted rapid adjustment of thread processing diameter takes only about 10 minutes each time;

- The thread rolling of the production line adopts high-speed rolling process and special rapid tool withdrawal mechanism;

- The wire roller adopts high-quality materials and technology, and its service life can be several times that of conventional products, so as to avoid frequent replacement of accessories.

[automatic steel bar sawing and rolling wire production line] Click to view the product details

五隆兴科技发展有限公司

五隆兴科技发展有限公司