Beijing Wulongxing won the excellent enterprise brand promotion of China Construction and Research Institute Certification Center!

Recently, our company’s reinforcement mechanical connection joint and WL double screw sleeve reinforcement joint have been listed in the recommended list of certified suppliers of construction projects – and the list of excellent enterprise brands of China Construction and Research Institute Certification Center!

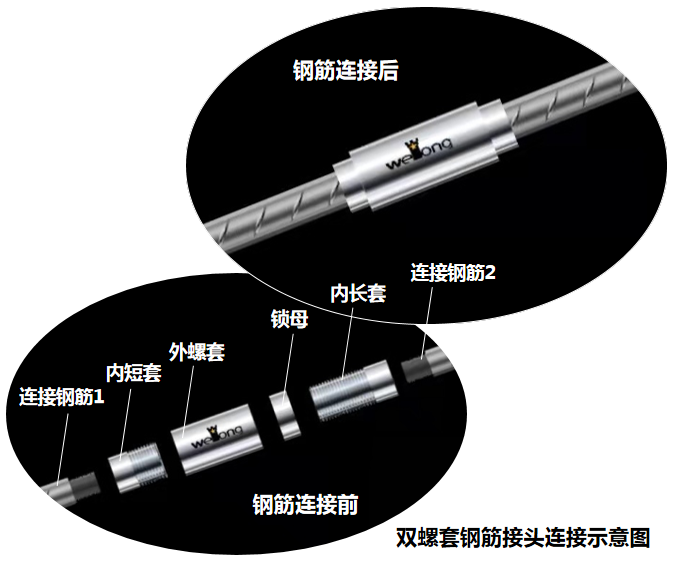

WL double screw sleeve reinforcement joint

Mechanical connection joint of reinforcement

Premier Li Keqiang stressed at the national teleconference on deepening the reform of “release, management and service” that “product certification management is the basic institutional arrangement to strengthen quality management and improve market efficiency under the condition of market economy” and “all those closely related to consumer life and can ensure product quality and safety through certification shall be converted to certification”. Product certification plays an important role in improving China’s product quality and guiding China’s industrial transformation and upgrading.

Voluntary product certification evaluates the quality, environmental protection, safety, reliability, compatibility, interoperability, efficiency and effectiveness of products, helps to guide product quality upgrading, increase effective market supply, improve market trust mechanism and create a good market environment.

As a comprehensive certification technical service organization integrating certification, standard setting, scientific and technological research and development, international cooperation, publicity and training, the certification center of China Academy of Building Sciences Co., Ltd. issues certificates to the products of the following excellent enterprises to prove that their products meet the social needs in the fields of quality and safety, low-carbon environmental protection, resource conservation and so on.

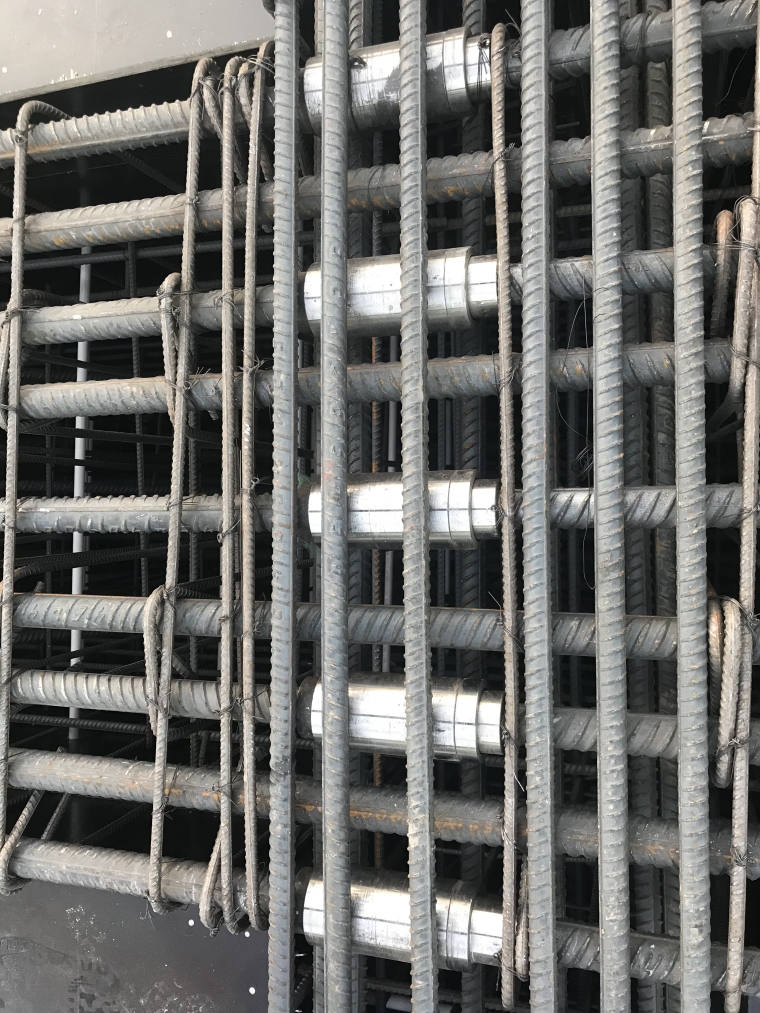

WL双螺套钢筋接头应用在超长钢筋笼对接

WL double screw sleeve reinforcement joint

The rib stripping and rolling straight thread reinforcement connection technology independently developed and produced by Beijing Wulongxing Technology Development Co., Ltd. has a history of more than ten years. It is a long-term product service provider of CSCEC and China Railway.

Over the years, the company has been adhering to the management concept of “quality first and reputation first” and constantly improving products and technology. Whether it is steel bar straight thread rib stripping and rolling machine or rib stripping and rolling straight thread sleeve, it has been trusted and affirmed by CSCEC, China Railway and other customers. The rib stripping and rolling straight thread joint produced by the company passed the product certification of the certification center of China Academy of Building Sciences in 2016.

Mechanical connection joint of reinforcement

The joint is composed of four connecting pieces: inner screw sleeve: 1, inner screw sleeve, 2, outer screw sleeve and lock nut, which are combined with externally threaded reinforcement.

Characteristics of joint:

● It is especially suitable for the connection of parts where the connecting reinforcement cannot rotate and the position error of the connecting reinforcement is large, and the connection quality can be guaranteed to meet the deformation performance requirements of class 1 joints of the industry standard under the condition that the middle of the reinforcement is not on the top;

● The connection is fast and convenient, and can bear the force after the connection is completed;

● Whether the joint quality is qualified or not, the joint appearance and torque can be visually inspected, and the installation torque can be inspected, which is simple and clear;

● No other machines, tools and equipment are required for connection operation, only a wrench is required;

● The joint has high quality and reliability, can fully meet the performance of 500MPa grade 1 joint, and can be connected at the same section of the structure, which is convenient for construction.

Applicable fields of joints:

Nuclear power project – connection of large-diameter vertical reinforcement mesh parts, connection of formwork free floor slab, reinforcement connection at the last joint of portal and annular reinforcement, spot inspection part of on-site joint, post cast strip and other special parts.

Bridge Engineering – connection of reinforcement parts such as foundation reinforcement cage, pier body reinforcement parts, tower body reinforcement parts, ground connecting wall reinforcement mesh, etc.

Prefabricated building — it can completely replace semi grouting and full grouting joints, and can be used for mechanical connection of vertical and horizontal reinforcement.

High rise core tube structure — mechanical connection of reinforcement parts, reinforcement parts and section steel parts.

Track engineering – mechanical connection of integral reinforcement of pier body components or reinforcement parts of viaduct.

Solve the problem that the reinforcement connection is not collinear

- By simply adjusting the relative position of the connector during connection, the track lines of the upper and lower threads of the butt reinforcement can be adjusted from non collinear to collinear!

- It can completely solve the problem of reinforcement connection of parts in building industrial construction.

It can completely solve the problem of reinforcement connection of parts in building industrial construction.

- High strength, simple operation, fast construction speed and good force teaching performance.

- Provide technical training and equipment maintenance services on the construction site in the later stage.

No pollution, all-weather construction

- The utility model has the advantages of convenient, fast and simple connection, no electricity for construction, no wind or rain, and can be constructed all day.

- Meet the corresponding environmental protection requirements, operate without open fire, and the construction is safe and reliable;

五隆兴科技发展有限公司

五隆兴科技发展有限公司