Let’s take a look at the centennial history of architectural industrialization!

Le Corbusier developed a small prefabricated house called citrohan (homonymous with Citroen)

Fuller named the house he wanted to create Ford. Early modernist pioneers dreamed of the construction industry like the automobile industry

模数化制造

模数化制造

Le Corbusier, the earliest prototype in the Maison citrohan series, Maison domino, 1944

“Build” or “manufacture”

What is the difference between construction and manufacturing? Construction is a process of separation between design and construction, and manufacturing is like producing standardized and modular parts in the factory. On site assembly is accurate and strict. The earliest prefabricated buildings can be traced back to the wooden frame assembled houses used during the immigration to America in the 17th century. The idea and implementation process of the earliest prefabricated apartment were put forward by John Alexander Brodie, an engineer in Liverpool, England, in the early 20th century. The uncle even invented the goal net of the football field. However, Brodie’s idea was not widely accepted in Britain, Instead, it became popular in Eastern Europe.

John Alexander Brodie(1858~1934)

In 1903, John Alexander Brodie used precast concrete as building material in the construction of Eldon street in Liverpool

Eldon street, 1964

(despite the invasion of war, Ren is a rigorous product of building industrialization)

Throughout the development history of architectural industrialization

Especially the development of industrialized housing

Important opportunities and driving forces

Mainly from the following aspects:

(1) Industrial Revolution

The progress of technology has brought the development of modern building materials and technology. At the same time, urban development has brought a large number of farmers to the city, resulting in the rapid development of urbanization and the serious problem of urban housing.

During the industrial revolution, a large number of farmers flocked to cities

An important achievement of the Industrial Revolution: the first large prefabricated public building — London Crystal Palace

(2) Demand caused by war and disaster

The real high-speed development of building industrialization began after the Second World War. European countries and Japan have a serious housing shortage. They urgently need to solve the housing problem and promote the development of prefabricated buildings. For example, Le Corbusier, a French master of modern architecture, once conceived that houses could be industrialized into mass production like automobile chassis. His book “towards new architecture” laid the foundation of the most cutting-edge architectural theories such as industrialized housing and residential machinery. In order to promote international exchanges and cooperation in construction products, construction standardization has also developed greatly.

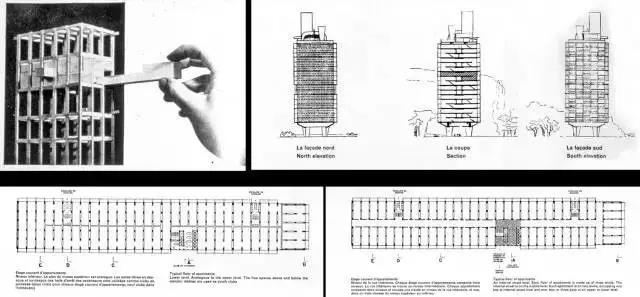

Under the background of large-scale post-war reconstruction, kobusier’s series of residential units based on modular system and standardization, and the urban reconstruction caused by the 1952 disaster are typical of Tashkent, the capital of the Republic of Uzbekistan. A major earthquake in 1966 destroyed one-third of the living area of the ancient capital Tashkent overnight, leaving 300000 people homeless, Almost all the cultural relics and historic sites have been seriously damaged, and urban reconstruction is imminent. In the next two years, the Soviet government rapidly rebuilt the city in an industrialized way, and built 23 million square feet of houses and 15 schools, of which 60% of houses and 70% of schools were prefabricated buildings. Tashkent became a typical city for industrialized reconstruction.

Tashkent urban housing rapidly constructed by industrialization

(3) Urban construction dominated by communism and utopian thought

这The representative of this aspect is the Eastern European countries with the Soviet Union as a typical example. Under the guidance of utopian thought, urban construction should be carried out quickly, so as to quickly establish an industrial civilized society by continuously increasing the working class and reducing farmers. During this period, the construction industrialization of the Soviet Union developed greatly. Firstly, the standardization of building components and the method of prefabrication and assembly were carried out in the industrial buildings in the 1930s. After the Second World War, in order to build a large number of houses, schools and hospitals, stereotyped design and prefabricated components have developed greatly. From 1958 to 1962, the “economic housing” of two or three finalized units began to adopt industrialized production; From 1963 to 1971, the number of finalized unit designs suitable for different climatic regions increased to 10.

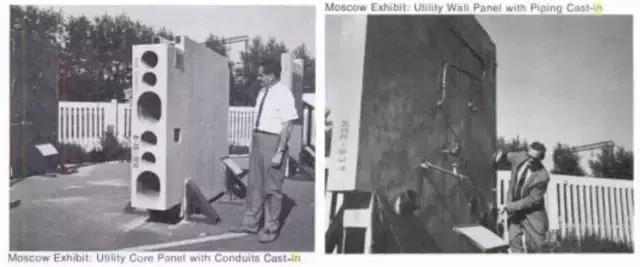

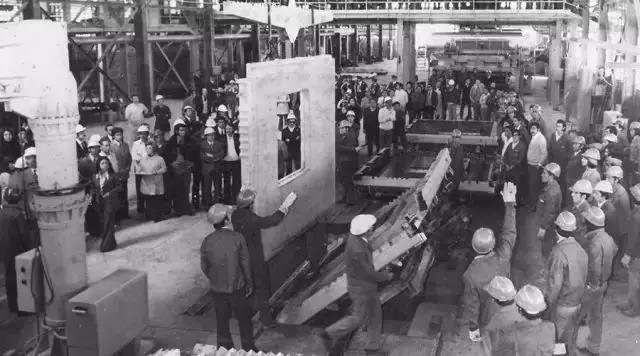

Moscow Exhibition in the 1960s: concrete precast slab embedded in conduit and unit wall embedded with water pipe

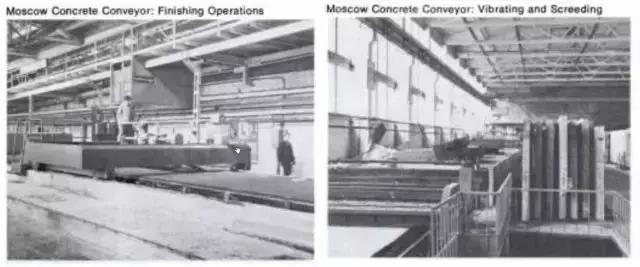

Moscow concrete conveyor belt: complete production, vibration and mortar grinding

At that time, the typical apartment module was assembled on site

In the development of more than a century, the characteristics of industrialized housing are different in different periods, with different technical levels and the needs of the times. In the process of building industrialization, the exploration of standardization and modulus system is of great significance. The higher the degree of standardization often means the reduction of cost and the shortening of construction period. The standard modulus must also adapt to the local construction conditions at that time, meet the characteristics of assembly and mechanization, be flexible and meet the exchange requirements, The module body should also have strong applicability to meet the needs of various building types.

From 1931 to 1981

There are 28 kinds of prefabricated concrete building systems in the world

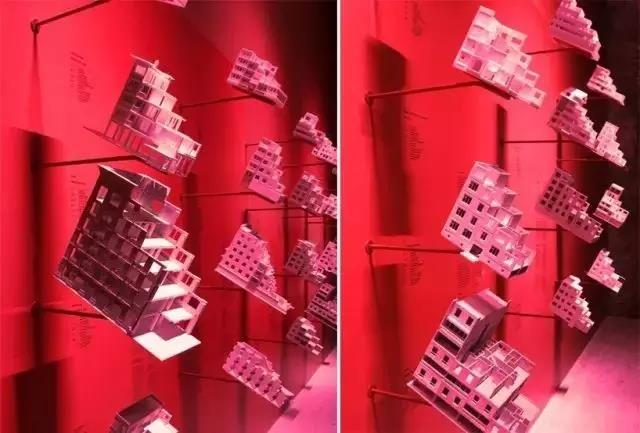

2014 Venice Biennale Chile Pavilion

From 1931 to 1981, there were 28 kinds of prefabricated housing systems all over the world

Building industrialization 1.0 Era

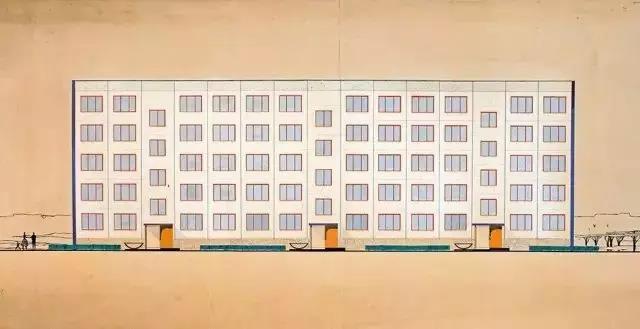

“Khrushchev building” laid the foundation for the large-scale construction of early prefabricated buildings

The traditional masonry construction was slow and could not meet the needs of crowded cities. In order to improve the serious housing shortage in Moscow, in January 1950, under the supervision of Khrushchev (then Secretary of the Moscow Party committee), a convention on architects of the former Soviet Union with the goal of low cost and quick effect was reached.

Two precast concrete factories were built in Moscow in 1953 and 1954. After continuous performance and structural tests, the performance of precast concrete has been proved to be excellent.

In 1961, Vitaly Pavlovich Lagutenko designed a five storey prefabricated concrete building, which is the famous “Khrushchev building”

Vitali Pavlovich thought that the elevator cost was too high and affected the construction speed, so he set the height at five floors

Subsequently, large-scale construction was carried out, and a large number of “Khrushchev buildings” have been retained in the belyayevo region of Moscow

In the late 1960s, with the growth of demand, the height reached 16 floors

Chilean practice

In 1972, the former Soviet Union donated a construction industrialization assembly line to the Comintern of Chile and established a factory called KPD. By 1978, 153 industrialized houses had been produced and manufactured

KPD plant in Chile

The concrete panel produced by KPD factory was installed on the Chilean construction site in the 1970s. The characteristics of this period are: fast, large quantity, low price, single material, and most of the design and construction are relatively rough. However, there are also some examples of the combination of technology and art, such as the famous building Marseille apartment, residence 67 in Montreal, Marina city in Chicago (i.e. corn building), Residence 67 Montreal, 1967.

It consists of 354 fully prefabricated “boxes” for each residence, with the size of each basic unit of 38×17 square feet, and the kitchen and bathroom are also prefabricated modules in advance. The innovation of No. 67 residence lies in the combination of suburban garden residence and urban high-rise apartment. The construction method was called “three-dimensional modular construction system” at that time.

“Box” being assembled

Marina City, Chicago, also known as “corn building”, 1964

Marina city is a mixed residential and commercial building. Its buildings contain two 61 story, 179 meter (587 foot) high residential buildings. It has become a landmark of Chicago because of its unique shape similar to corn cobs. The architect Bertrand Goldberg is a student of Mies van der Rohe. The design idea of Mario city is influenced by Mies, but Goldberg’s assumption of prefabrication, modulus and curve form has become the biggest highlight of the project.

玉米楼是当时世界最高的混凝土建筑

Building industrialization 2.0 era

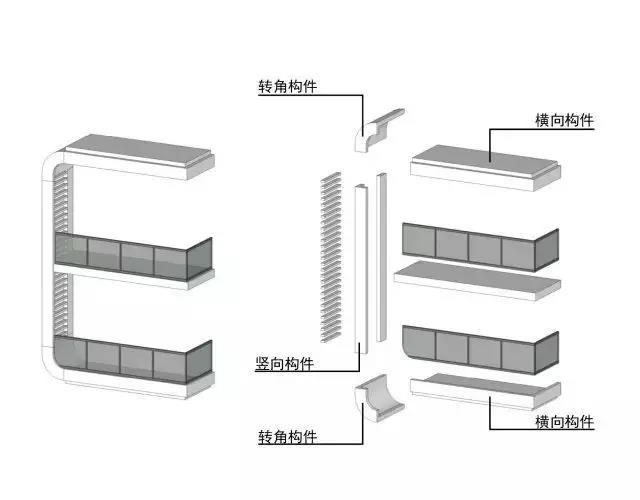

In the late 1960s and after the 1970s, with the development of technology, the size of components increased and the modular system became more perfect. Prefabricated components are reduced by the restrictions of shape and materials, and industrialized residential products can be customized by more customers. During this period, the prototype of composite wall, also known as sandwich exterior wall panel, appeared The interior of this kind of wall panel is honeycomb structure, and light materials for thermal insulation are added. The shape of concrete exterior wall panel is also more and more diversified. Later, prefabricated buildings pay more attention to the integration of aesthetics, function, structure and economy.

Some precast concrete products at that time

“City of the sky” in the suburbs of Paris

In the 1980s, grand Nova West in the eastern suburb of Paris built a large-scale postmodern utopian community for a large number of immigrants. This postmodern community with the meaning of “city of the sky”. Its landmark building is a reinforced concrete giant with 610 apartments. The external surface of the building adopts prefabricated system, including large-scale prefabricated components, with distinct personality.

The large-scale prefabricated components on the facade are highly decorative. In the post modular era and the era of building industrialization 3.0: high efficiency, integration, energy saving, new materials and new technologies, they are more personalized and stylized, extending from residential buildings to public buildings.

New York Mini apartment project, 2015

The nine story Mini apartment project is intended to provide affordable Mini apartments for young people in New York City, where the population is increasing year by year. The project consists of 55 prefabricated units, each with an area of 370 square feet and a floor height of 10 feet. The residential units of the project, including equipment decoration, are completed in the factory, and the construction is assembled on site, which greatly reduces the construction cost, improves the construction speed and the living quality of the mini apartment.

The standard unit of personalized Mini apartment in New York, highly integrated customization including furniture and facilities, China’s housing practice in the era of industrialization 3.0, and a large community of plot 3a-03a of Xincheng first station, Qingpu District, Shanghai.

The project was designed and completed by East China urban design and Research Institute of Huajian group in 2016. The project adopts advanced PC prefabricated laminated shear wall structure system, and the proportion of prefabricated residence is 100%. The design explores the product characteristics of the architectural industrialization 3.0 era. Li Jun, the project leader and chief architect of East China urban design and Research Institute of Huajian group, believes that there should be a breakthrough in standardization and personalization in the post modulus era.

Post modular era – highly organic standardization

The first mock exam is designed in accordance with the building modulus system (2M, 3M and a small amount of 1M and 1/2M). It creates conditions for the size coordination and interchange of the components and components, and facilitates the factory to make unified processing. Unify the bays of residential buildings in dense sections; Unified window opening on four sides; Unify the dimensions of stairs and elevators; Unify the size of tube wells in different rooms; Measures for unifying floor heating and fresh air devices; Unify the standards of building and indoor fine decoration.

Post modular era – customization

The carefully designed and selected facade module is suitable for the modeling requirements of personalized facade of different groups.

What will happen in the era of industrialization 4.0?

1.0 era blurs the boundary between design and construction, while 4.0 era will redefine the dominant position of design, and architectural design is no longer limited by modulus!

With the maturity of BIM Technology and the entry of high-tech means such as 3D printing into the construction field, it is entirely possible for the future industrialized buildings to realize the original vision of modernist masters to “manufacture residential products like manufacturing cars”, and even leave us more imagination space.

3D printing structure replaces traditional reinforcement

In the future, there may even be construction sites monitored by UAVs based on BIM Technology. In the era of personalized buildings returning to craftsmen, the residential industry closely related to daily life will move towards a higher level of industrialization. Perhaps in the near future, we will be able to feel the industry changes and even the changes in the face of the city brought about by new technologies.

(this article comes from the Internet. If there is infringement, please contact to delete it.)

五隆兴科技发展有限公司

五隆兴科技发展有限公司