In the construction of road and bridge, high-speed railway station, nuclear power station, rail transit and other large projects, the traditional steel bar straight thread threading production line is used for steel bar processing, which often faces the following pain points:

- Insufficient efficiency of single machine

- Multiple machines cover a large area

In case of tight construction period and large amount of straight thread threading in large projects, the use of traditional straight thread threading production line for reinforcement processing will lead to a large amount of space occupied by the overall scheme and inconvenience in production and transportation.

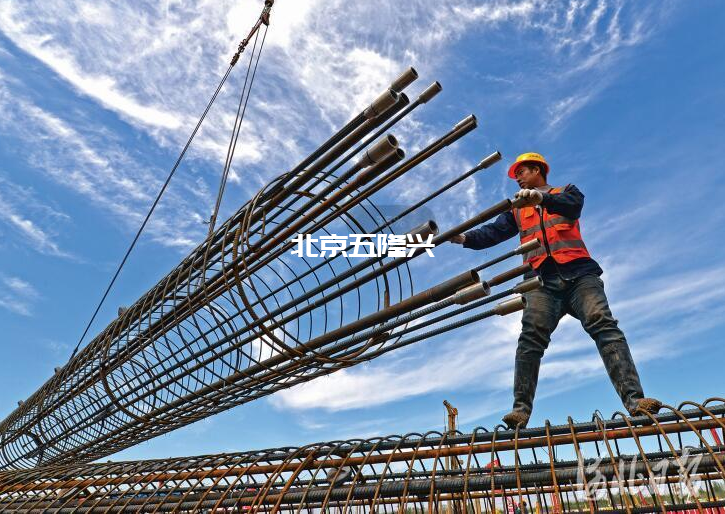

Live shooting of products of Wulongxing production line

Wulongxing production line is widely praised in the use of the project

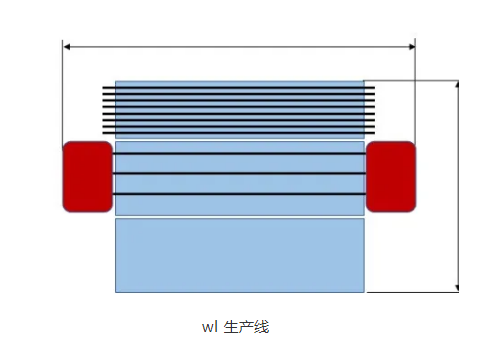

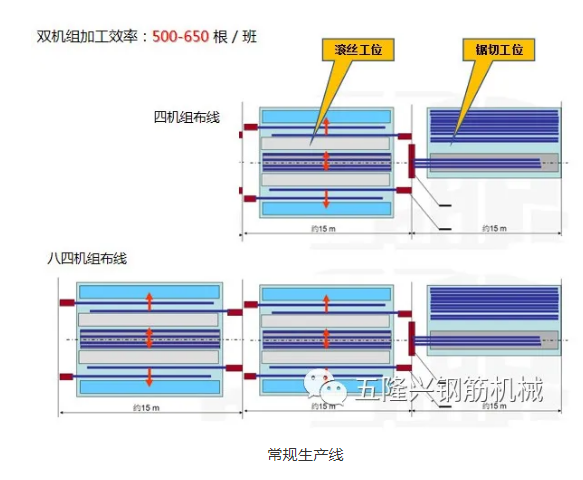

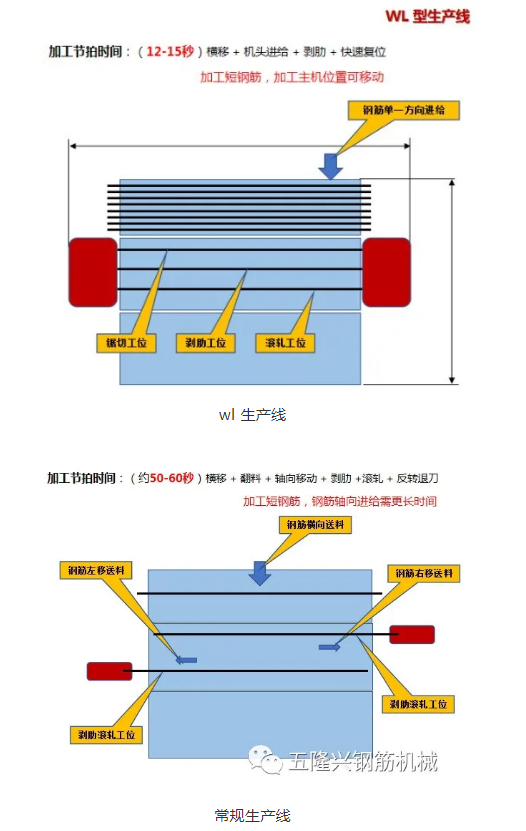

The intelligent rebar thread rolling automatic production line independently developed by Beijing Wulongxing is invested in the project. The comparison with the ordinary thread production line is as follows (hereinafter referred to as WL production line):

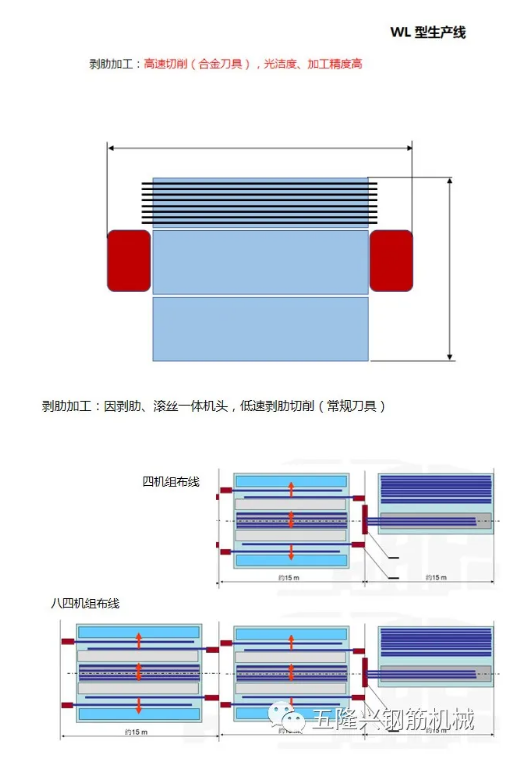

一、Wiring mode and floor area:

Full functions of reinforcement processing: the production line can integrate the two main functions of reinforcement sawing and thread processing on the same production line, while the conventional production line is arranged with the two lines of cutting production line and thread processing production line;

Small land occupation of the production line: the production line adopts high-speed milling processing technology, and the milling device is arranged in front of the thread processing device, eliminating the land occupation of the conventional shear production line;

二、WL high efficiency processing and reasons:

“Exquisite structure and easy transportation”. The intelligent steel bar thread rolling automatic production line has exquisite structural design. The whole production line occupies a small space (10m * 16m), has low requirements for site space, modular design, easy disassembly and convenient transportation transfer. Wiring can be produced even in the narrow construction area of the city, saving the cost of secondary material transfer;

三、Reasons for high quality of WL processing:

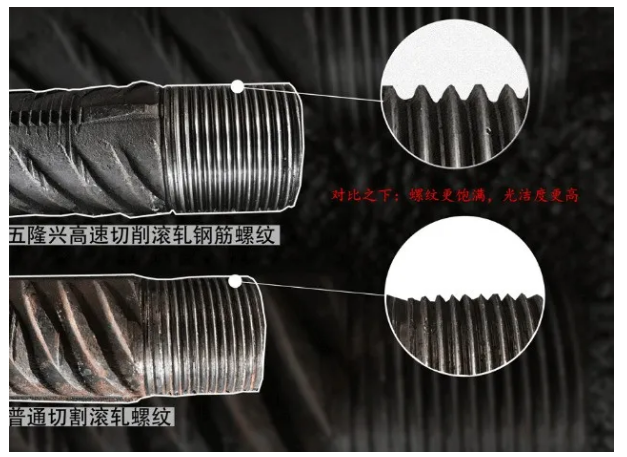

“High quality”. Due to the separate processing method of rib stripping and wire rolling of reinforcement, the rib stripping cutting can adopt alloy tool for high-speed cutting, with high surface finish and dimensional accuracy of reinforcement and excellent thread quality;

The thread accuracy can reach grade 6, and is not disturbed by any external conditions and personnel factors, with good consistency. The processing quality of steel wire head is good Intelligent dimension sensing identification system for rib stripping and wire rolling. The processing quality of wire head meets 100% of the specification requirements, completely solves the quality defects of reinforcement wire rolling, and “zero” rework;

Comparison of thread quality between Wulongxing production line and other production lines

In addition, the intelligent steel bar thread rolling automatic production line independently developed by Wulongxing has the following characteristics:

(1) “Exquisite structure and easy transportation”. The intelligent steel bar thread rolling automatic production line has exquisite structural design. The whole production line occupies a small space (10m * 16m), has low requirements for site space, modular design, easy disassembly and convenient transportation transfer. Wiring can be produced even in the narrow construction area of the city, saving the cost of secondary material transfer;

设备在工厂组装后,经过测试即将交付

(2) “Man machine dialogue”, no matter equipment failure, regular maintenance or regular tool replacement, it will alarm and prompt possible fault points and problem solutions; The steel bar blanking adopts double head simultaneous sawing and blanking setting, and the steel bar is cut to length with a length error of 1mm.

故障灯快速示警

更换刀具提示

(3) “Low cost of consumables” , Self developed special rib stripping and wire rolling tools for reinforcement, with super hard and super long service life, and the cost of a single reinforcement processing tool is less than 0.02 yuan; The super long durability can ensure that the tool does not need to be replaced for a month or even a few months;

(4) “Excellent workmanship” , The first-line brand suppliers are preferred to provide the installation of key parts, “Siemens motor”, “Youyan hydraulic valve”, “Taiwan oil pump motor and oil pump”, “Taiwan Shangyin guide rail”, “Mitsubishi PLC controller” and “France Schneider Electric”. The equipment has high durability, stable operation and low failure rate;

(5) “Wide application range”, One production line can simultaneously complete “single double head threading”, “single single head threading”, “two double heads threading with the same or different specifications”, “one positive wire and one reverse wire” and “ultra short steel bar specimen threading”

The intelligent steel bar thread rolling automatic production line can reduce the labor cost and optimize the processing process in an all-round way. Under the background of the government’s strong support for the development of prefabricated buildings, Wulongxing intelligent reinforcement thread rolling automatic production line, as an advanced productive force, conforms to the development trend of the industry. It is a revolution in the field of reinforcement engineering industrialization and has completed its mission of high efficiency, less manpower and less land occupation given by the times! It is also the only way for the digital upgrading of the reinforcement processing plant. Choosing Wulongxing intelligent reinforcement thread rolling automatic production line is a very valuable investment!

五隆兴科技发展有限公司

五隆兴科技发展有限公司