Common problems, analysis and solutions in engineering application of reinforcement straight thread extended thread joint

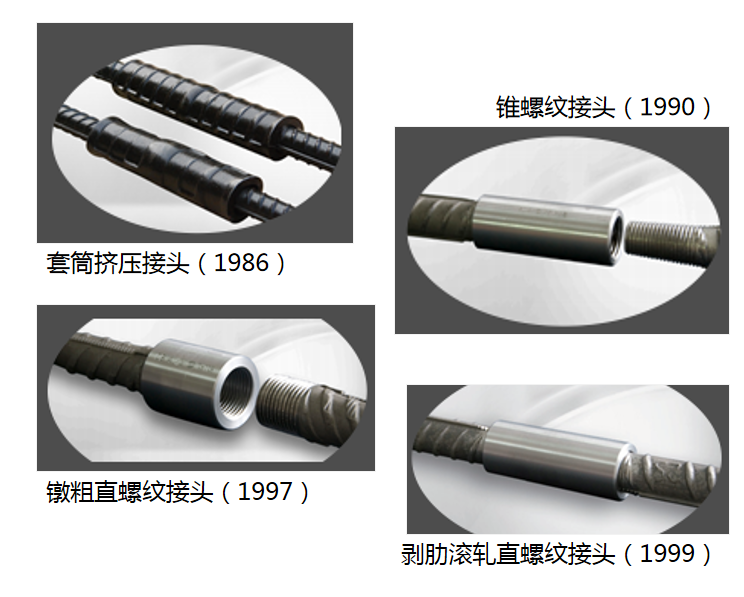

There are several main types of reinforcement mechanical connection in China:

At present, in China’s Construction Engineering, since the 1980s, the mechanical connection technology of reinforcement has been widely popularized and applied. Among the commonly used types of reinforcement joints, such as sleeve extrusion joint, conical thread joint, upsetting straight thread joint, direct rolling straight thread joint and rib stripping rolling straight thread joint, the commonly used standard joints are of reliable quality due to their simple processing technology and equipment, low connection cost and convenient connection, It accounts for more than 90% of the market share of reinforcement mechanical connection joints.

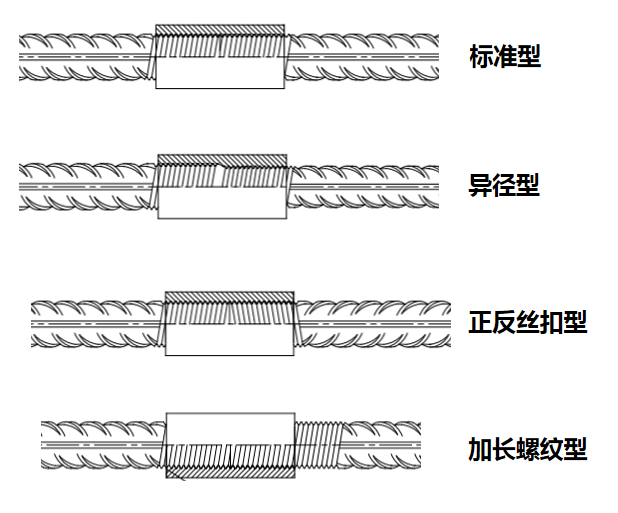

Main types of rib stripping rolling joint:

The main joint types of rib stripping and rolling straight thread joints are: standard type, reducing type, flared type, welding type, positive and negative screw thread type, extended thread type, etc. different types of joints can be selected for different application scenarios. Among them, the extended threaded joint is widely used.

Connection characteristics and main application scenarios of extended threaded joint:

Connection process of extended threaded joint: first connect the straight thread sleeve to the reinforcement on the long thread side. After the connected reinforcement is in the butt joint position, rotate the sleeve to the reinforcement to be connected on the short thread side

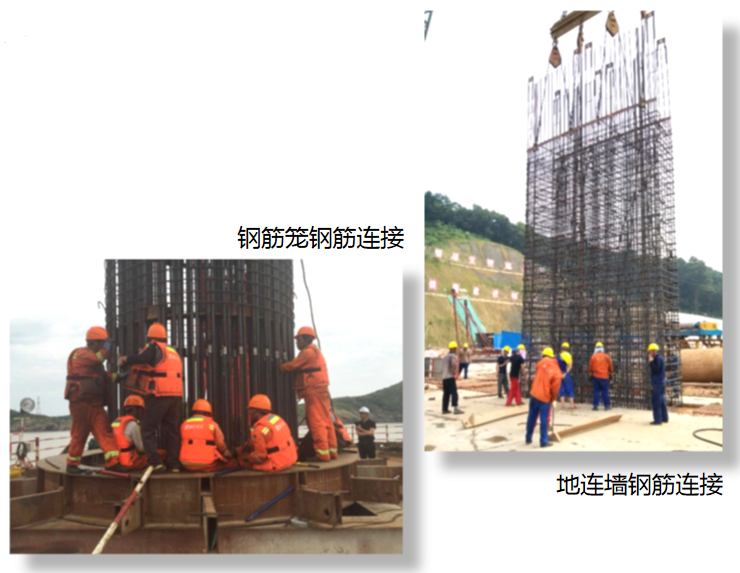

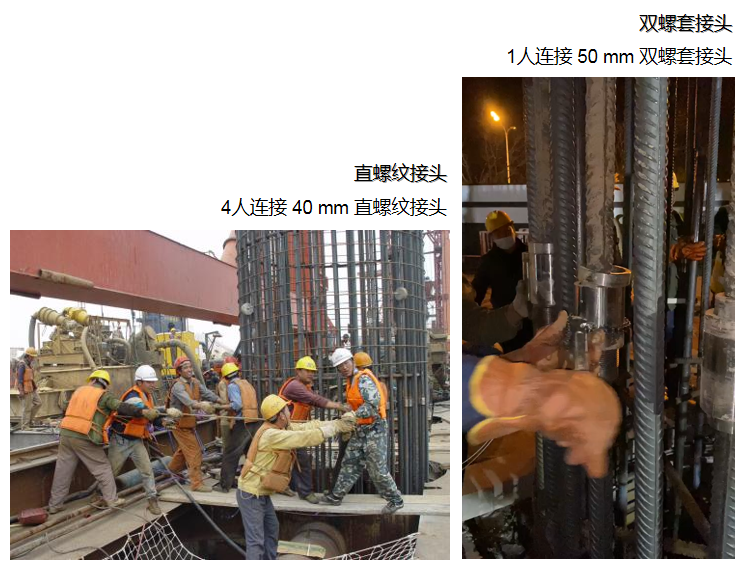

Connection features of extended threaded joint: the connection of reinforcement can be completed without rotating the reinforcement, or slightly rotating and tightening the reinforcement after connection. In the connection of reinforcement parts of reinforcement cage, because the connecting reinforcement cannot rotate, the middle of the connecting reinforcement cannot be tightened.

Main application scenarios of lengthened threaded joint: foundation reinforcement cage, ground connecting wall, reinforcement connection with “knee reinforcement”, etc.

Main problems of extended threaded joint connection:

(1) Low joint strength (broken on exposed thread):

Because the rib stripping and rolling process is adopted, the cross-sectional area of reinforcement is reduced due to rib stripping and cutting. Even if the cold rolling and rolling process is adopted to slightly improve the surface strength of reinforcement, it is not enough to compensate for the reduction of reinforcement cross-section and strength caused by rib stripping.

The damage of this joint is basically at the exposed thread part of the joint section. Due to low strength, class II joints specified in standard jgj107 are mostly used in the design of such joints, and the joints are not arranged in the same section. Even so, when there is not much super reinforcement, the joint strength is still difficult to meet the qualified requirements.

(2) Low joint strength (sleeve internal thread pulled off):

Due to the equipment and technology of some manufacturers, it is easy to form excessive taper and pitch error in the processing of long thread of reinforcement (the error exceeds 0.2-0.3mm within the length range of sleeve). In order to facilitate the smooth screw in and installation of long thread end sleeve, the on-site operators can only reduce the diameter of reinforcement thread head, and often thread at the end of long thread reinforcement (connection part) The fit clearance with the connecting sleeve is out of tolerance, which weakens the strength of the end thread of the long threaded reinforcement and causes the joint to pull off in the sleeve.

(3) Difficult connection and joint quality assurance:

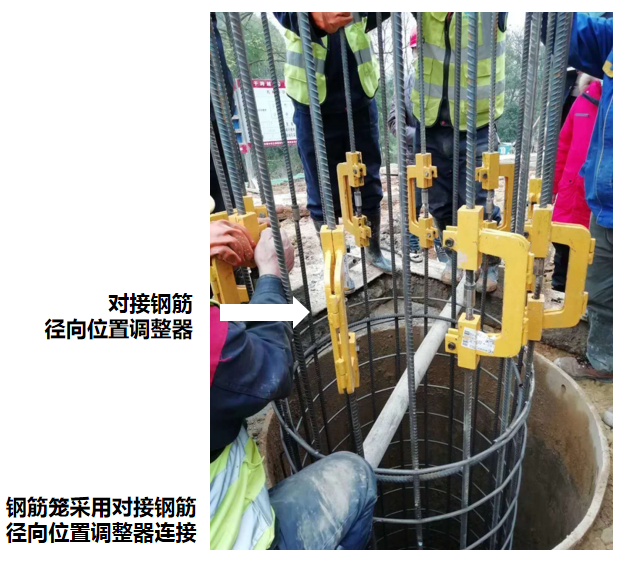

This situation is often seen in the overall connection of “reinforcement parts” such as reinforcement cage and ground connecting wall.

In order to ensure the accurate position of the upper and lower reinforcement threads during joint connection, the prefabrication process of “long line method” and “short line method” is mostly adopted during reinforcement cage prefabrication, that is, the ground mountain is paved for tens of meters or hundreds of meters, the main reinforcement is connected first, then the main reinforcement is welded and fixed with the stirrup, and then the butt mark is made to open each joint. When the reinforcement cage is connected, it is hoisted and connected according to the prefabrication position.

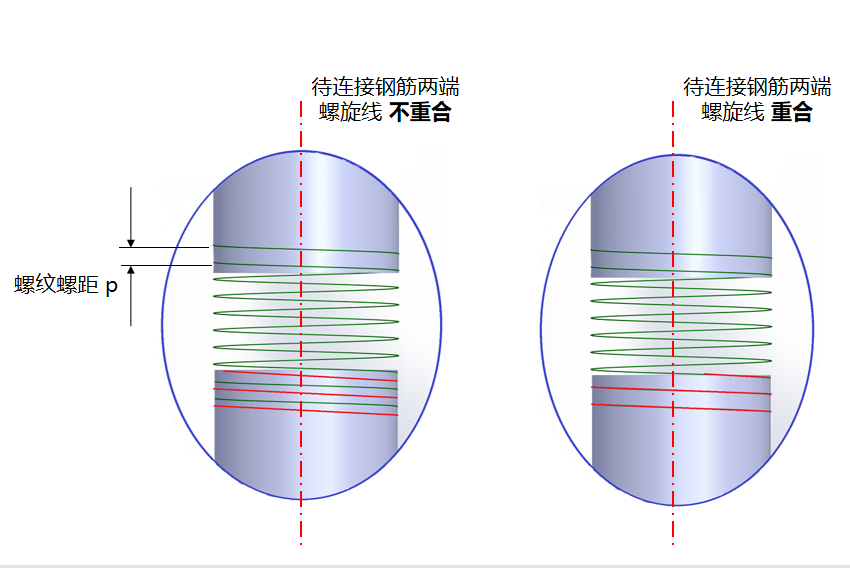

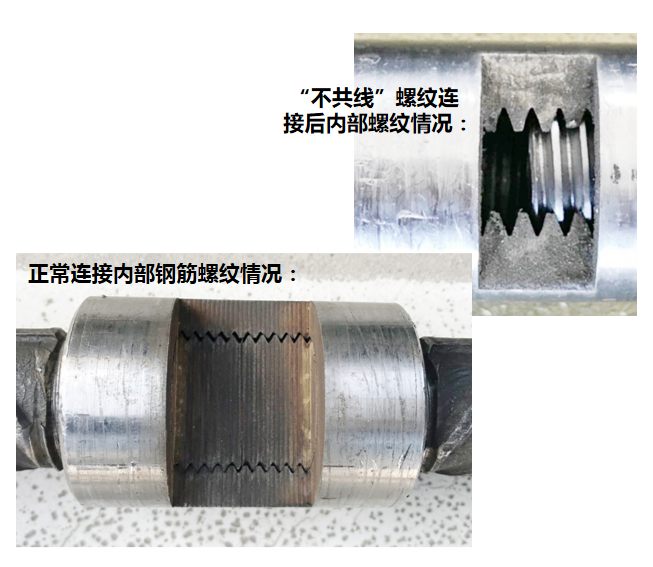

In this case, the main reason for the difficulty of connection is not the radial position deviation and deformation of stirrups, but the small deviation in the axial position of upper and lower connecting reinforcement during prefabrication, hoisting and installation of reinforcement cage, and the thread trace lines of upper and lower reinforcement are not collinear.

钢筋笼(钢筋部品)中上下钢筋的

螺纹轨迹线 的图示说明:

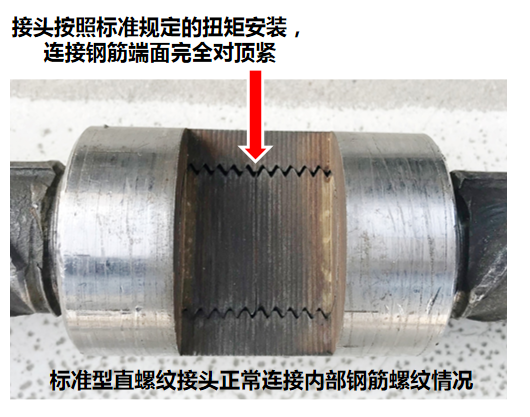

The thread pitch of domestic 25-40mm reinforcement straight thread joints is generally 3.0mm. When the processing accuracy of reinforcement and connecting sleeve thread is guaranteed, and the over tolerance of upper and lower thread trajectory is greater than 0.3mm, the connection is very difficult. Even if the joint is connected with super large torque (which may exceed more than 10 times the specified torque value), the connection thread has actually been damaged, Resulting in low strength of threaded connection.

At present, many employees in the industry are not very clear about the causes of this potential quality hazard.

According to 7.0.2 of the current industry standard technical specification for mechanical connection of reinforcement jgj107-2016 Article 1 clearly requires that “all types and types of joints shall be subject to process inspection, and the inspection items include unidirectional tensile ultimate tensile strength and residual deformation”.

If the joint process inspection is carried out in strict accordance with the standard requirements, the residual deformation in the process inspection cannot meet the qualified requirements when the “extended thread” joint cannot be tightened in the middle of the connecting reinforcement!

Solution of double threaded joint in “part” connection:

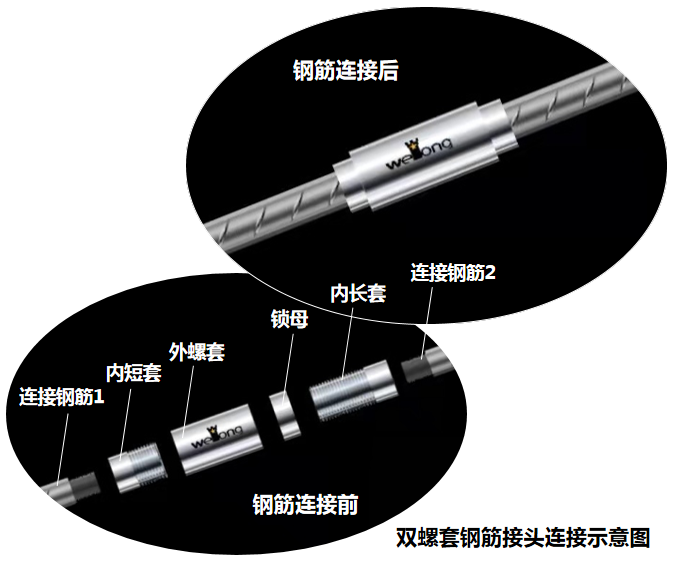

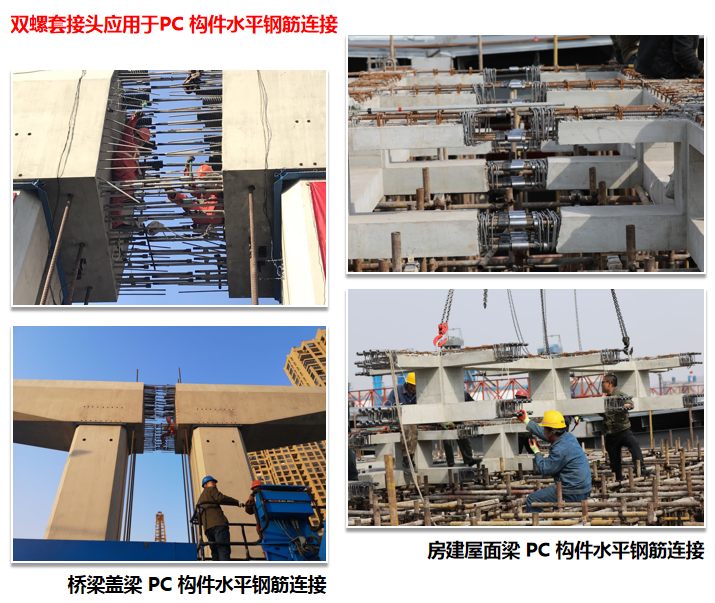

Because the ordinary straight thread reinforcement joint is not suitable for the “part” reinforcement connection under the background of building industrialization, the double screw sleeve reinforcement joint came into being in 2017.

Composition of double screw sleeve reinforcement joint: the double screw sleeve reinforcement joint is composed of connecting reinforcement 1, inner short sleeve, inner long sleeve, outer screw sleeve, lock nut and connecting reinforcement 2.

The biggest feature of double screw sleeve reinforcement joint connecting reinforcement: by simply adjusting the relative position of the connector during connection, the track lines of the upper and lower threads of the butt reinforcement can be adjusted from non collinear to collinear!

The double screw sleeve reinforcement joint solves the problem that the trajectory lines of the upper and lower connecting reinforcement threads are collinear in the straight thread connection of reinforcement. Therefore, the connection is smooth and efficient!

It takes 2-5 hours for the double screw socket joint to connect the ordinary straight thread joint to the connecting surface of a reinforcement cage to about 20 minutes, and the connection quality is 100% qualified!

Main engineering cases of double screw sleeve reinforcement joints: since 2017, the products have been introduced to the market, with specifications ranging from 22-50mm and a cumulative consumption of more than 700000 pieces.

The application types of double screw socket joints are: PC precast bridge bent cap, roof beam horizontal reinforcement connection

Combined connection technology of concrete beam reinforcement and rigid steel column

The application of these projects fully proves that the double screw socket joint can completely solve the problem of reinforcement connection of parts in building industrial construction. The main problems of rib stripping rolling straight thread lengthened threaded reinforcement joint in the reinforcement connection of ordinary reinforcement and parts are as follows:、

(1) Low joint strength;

(2) For the reinforcement connection of parts, it is difficult to connect and the connection quality is unqualified due to the non collinearity of the connecting thread track line;

(3) It is applied to the reinforcement connection of parts, and the residual deformation in the process inspection does not meet the standard requirements;

Therefore, the straight thread joint is not suitable for the reinforcement connection of “parts”, and the double screw sleeve reinforcement joint will be one of the alternative products!

五隆兴科技发展有限公司

五隆兴科技发展有限公司![[stiff column] the performance of double screw sleeve instead of welding is incredible! [stiff column] the performance of double screw sleeve instead of welding is incredible!](https://www.bjwlx.com/en/wp-content/uploads/2021/08/1-150x150.png)