In building structure, because of its excellent structural mechanical properties, rigid column structure is favored by many structural architects. Among them, there is the combined connection between section steel and reinforcement, and the combined connection between section steel, reinforcement and section steel and reinforcement. Among them, there is reinforcement wrapped in the outer layer of section steel (steel wrapped steel), and there is section steel wrapped in the outer layer of reinforcement (steel wrapped steel).

Next, we will introduce the method and characteristics of double threaded joint in the structural connection according to the first case above.

(1)Combined connection of section steel and reinforcement

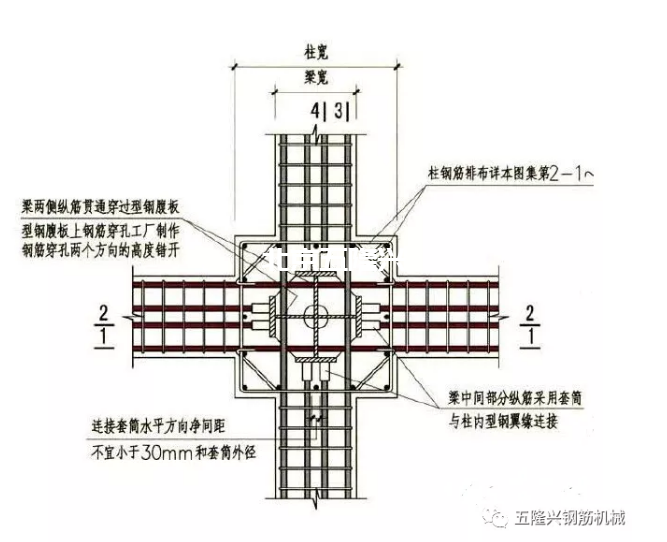

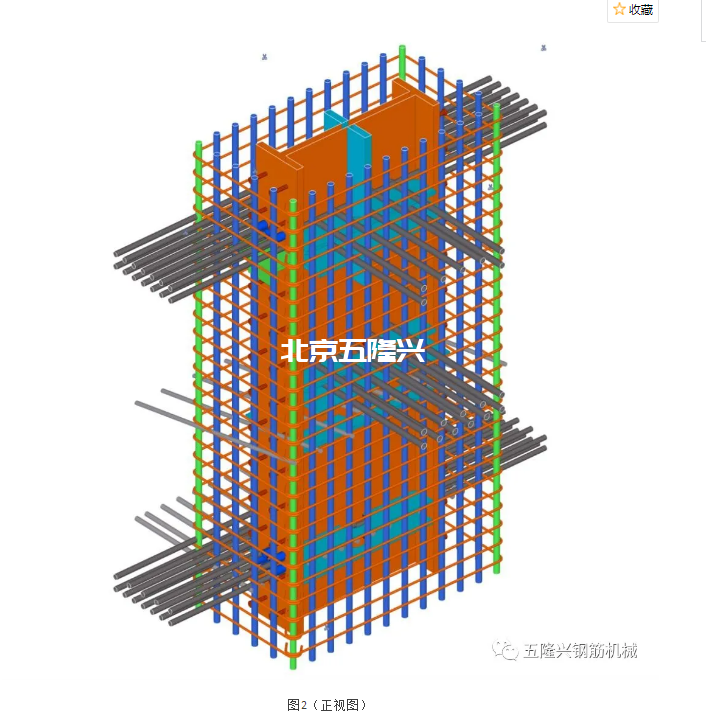

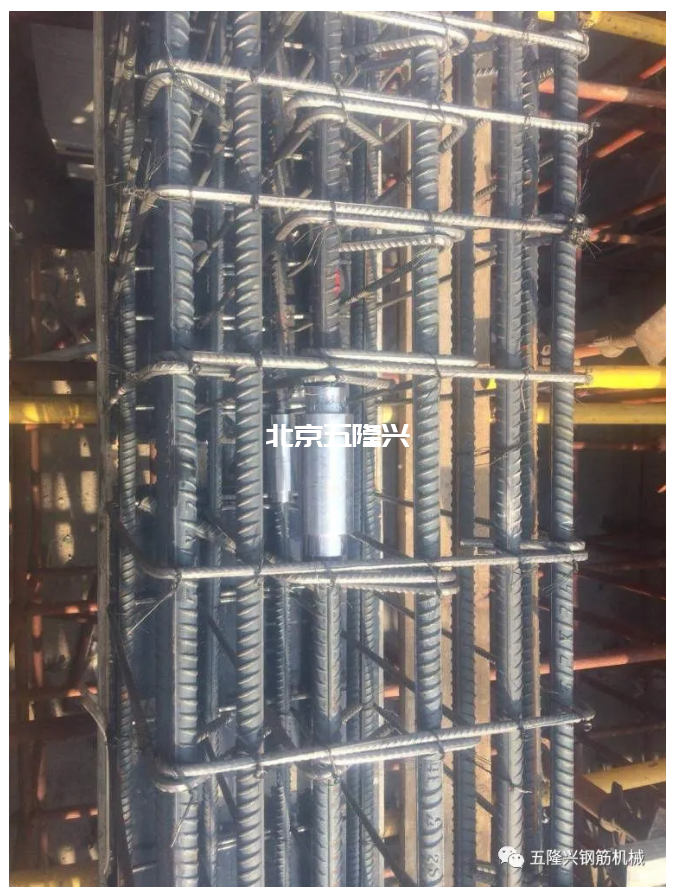

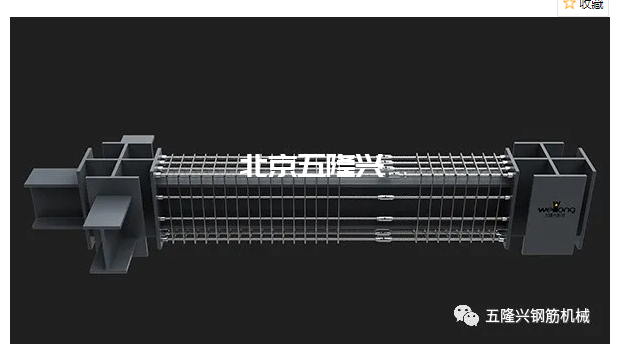

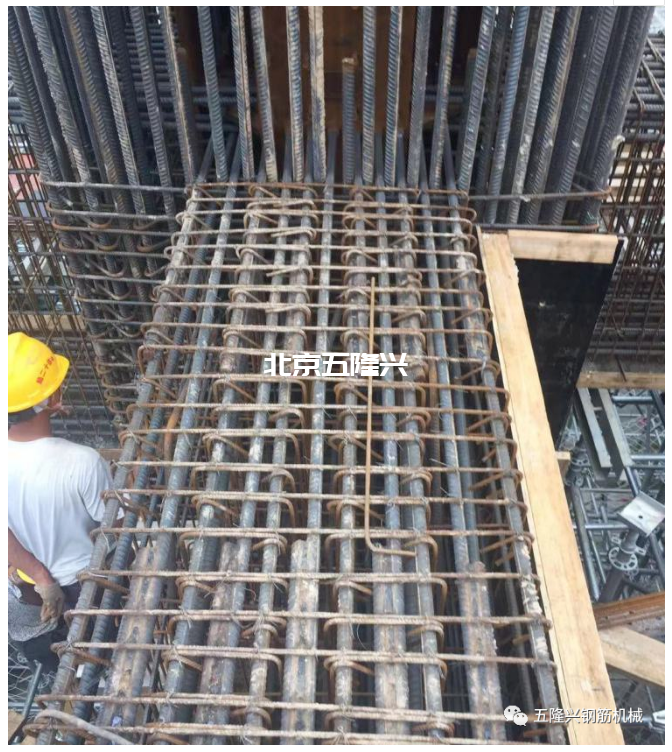

As shown in Figure 1 and Figure 2, the composite connection structure of section steel column and reinforced beam is shown.

Figure 1 (top view)

Previously, our common connection method is to use the cantilevered corbel on the steel column to connect it within the flange range of the steel column in the structural design. The flange plate of the outer steel column is 280mm wide, and the connecting plate is welded on the flange plate. For example, the reinforcement usually needs to be welded on the connecting plate to realize the connection between the reinforcement beam and the section steel column, as shown in Figure 2 (insert the photo of the connection of the method).

Using the original traditional welding connection method, the steel column flange overhanging steel corbel connecting plate is welded with the reinforcement. On site, it is not only difficult to weld the reinforcement, but also difficult to ensure the welding quality and the accuracy of the reinforcement position. Moreover, the on-site welding time is long, which often can not meet the requirements of construction period and quality.

一、Problem analysis:

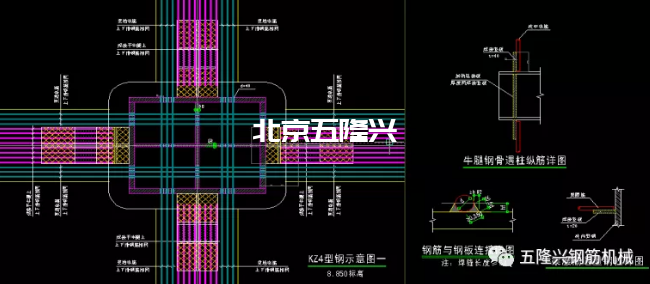

Figure 3 Structural diagram of flange plate welding connection between horizontal reinforcement and section steel column

(2)Construction aspect

① The spacing between reinforcement and adjacent connecting plates is too small, and the concrete is difficult to be vibrated and compacted.

② The reinforcement in the rigid column is dense, which is inconvenient to install.

③ The connection between frame beam reinforcement and section steel column is complex. The on-site reinforcement is connected with section steel column through connecting plate, and the on-site welding workload is large.

Under this working condition, why does the reinforced beam not use the reinforced straight thread joint to connect with the section steel column?

Under this working condition, if straight threaded joints are used for connection, welded straight threaded joints are generally used on both sides, and a straight threaded joint is used in the middle. When the two section steel columns are fixed, the connection sequence must be to connect the welded end joints on both sides first, and then the middle joint. In this case, the extended thread straight thread joint is generally used. However, once the two ends are connected and tightened first, the middle joint cannot rotate the reinforcement, and the middle of the joint cannot be tightened to ensure the deformation performance of the joint. Moreover, the rib stripping and rolling process can not ensure the reliable strength of the exposed long thread of the joint.

Double threaded joint solution:

(1)Connection scheme between single horizontal reinforcement and section steel column

Welded straight thread joint + double screw sleeve joint + welded straight thread joint can reduce a large number of welding operation time and welding quality risks, save the expensive cost of connecting steel plates and welding materials, and facilitate on-site operation.

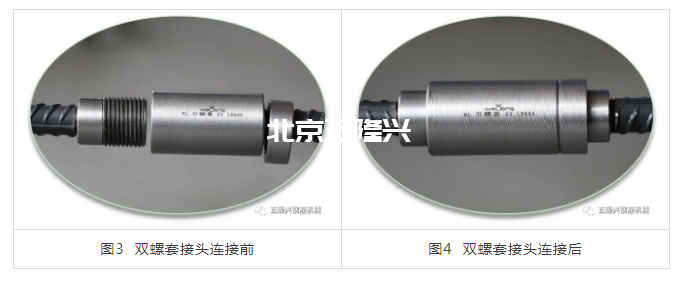

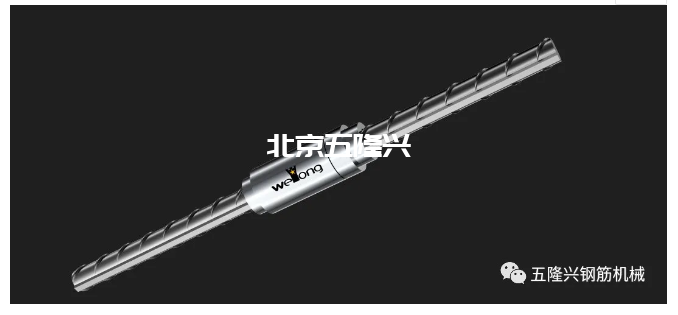

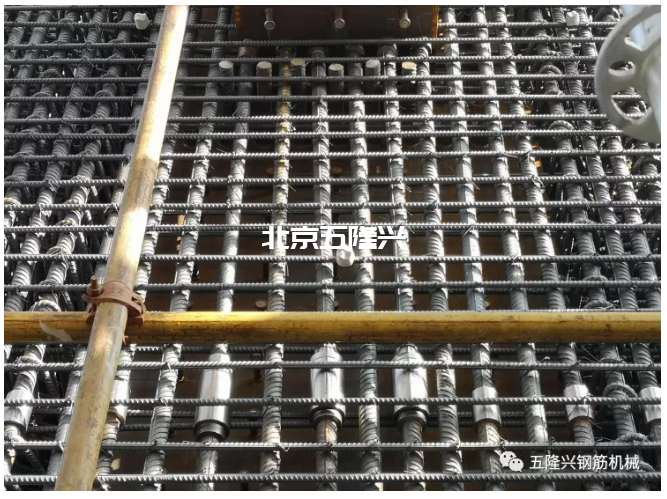

The structure of double screw sleeve joint is shown in Fig. 3 and Fig. 4. The pictures of the construction site after connection are shown in Figure 5 and Figure 6.

图5 焊接端照片

The new connection method uses welded sleeves at both ends of the rigid column and double screw sleeve for butt joint in the middle!

Figure 6 Photo of middle end of double screw sleeve

二、Technical features

The national patented product “WL double screw sleeve reinforcement joint” independently developed by Beijing Wulongxing Technology Development Co., Ltd. is mainly characterized by “reinforcement non rotation” connection. It has the characteristics of fast connection speed, convenient construction, reliable quality, low cost and all-weather construction.

The double screw sleeve has the following technical features:

① There is no wet operation at the connection joint, and it is fully mechanically connected; ② The connection is fast and takes only 20 seconds. After the connection is completed, it can bear the force;

③ Whether the reinforcement connection quality is qualified or not can be visually inspected, which is simple and clear;

④ The field joint quality inspection is simple and fast, which is consistent with the ordinary straight thread joint;

⑤ The reinforcement connection working face does not need its machines and equipment, but only needs to connect the wrench.

Several connection methods, you can choose the connection position according to the structural needs!

三、双螺套连接与焊接工艺对比:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Next, taking 32mm as an example, the cost of double screw sleeve connection and welding is compared in more detail.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|||

③ Electrode material,

④ stability of welding machine,

⑤ welding method

⑥ Measurement: comprehensive method technology of tensile, bending, impact and ultrasonic rebound

(二)Double screw sleeve:

Take 32mm diameter reinforcement as an example

|

|

|

|

|

|

|

|

|

|

|

|

|

||

四、Technical verification of double threaded joint:

It has passed the type inspection of hrb400e class I joint by the national construction engineering quality supervision and inspection center

Hrb500e class I connector

It has passed the “American Standard” type inspection of the national construction engineering quality supervision and inspection center

It has passed the fatigue performance test of 2 million times by the national construction steel quality inspection center

It has obtained the approval for the use of the National Nuclear demonstration project “Rongcheng nuclear power”

It has passed the “CABR” product certification of Chinese Academy of Building Sciences

[case] bottleneck technology of connection between reinforced concrete beam and steel reinforced concrete column

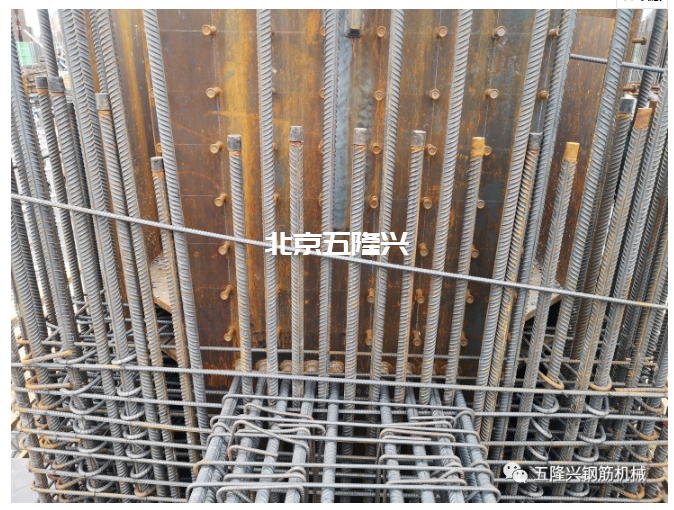

For the connection between reinforcement and section steel column, the quality control problems caused by connection will be encountered in many large public construction projects, as follows;

Figure 1: One end of the reinforcement is processed with straight thread and effectively connected with the section steel column through the welding sleeve. It has the advantages of convenient and fast, simple operation, stable and controllable quality, high efficiency and low cost.

Figure 2: because the reinforcement at the other end cannot rotate, the connecting plate welding operation is adopted. The features can solve the problem that the reinforcement can be connected with the section steel column when it cannot rotate, but there are many unqualified items of welding quality, difficult quality control, low connection efficiency, low qualified rate of flaw detection, unstable quality, large weight of connecting plate, high cost and difficult detection.

Figure 3: both ends are connected by welding sleeves. Because the reinforcement cannot rotate again, it is difficult to connect, so welding connection is adopted. The welding length loses raw materials, the welding quality is also uncontrollable, the welding operation time is long, the qualification rate is low, the efficiency is low, the flaw detection can not guarantee 100% qualification, and the detection cost is high, and the construction progress is difficult to guarantee.

Figure 4: a new type of fabricated mechanical connection process. The section steel and steel column are connected by welding sleeve. For the non rotating parts in the middle, the new mechanical connection method is adopted to connect the two non rotating reinforcement in situ. The connecting reinforcement will not produce displacement during connection, and only a connecting wrench is required for operation. The connection speed is one minute to complete the operation (the reinforcement is also a straight thread thread head), the on-site components are cut to reach the first-class joint strength, the batch connection quality is very stable, the operation time is greatly reduced, and the operability of quality acceptance is strong. There is no open fire operation on site, which greatly saves welder operation and cost.

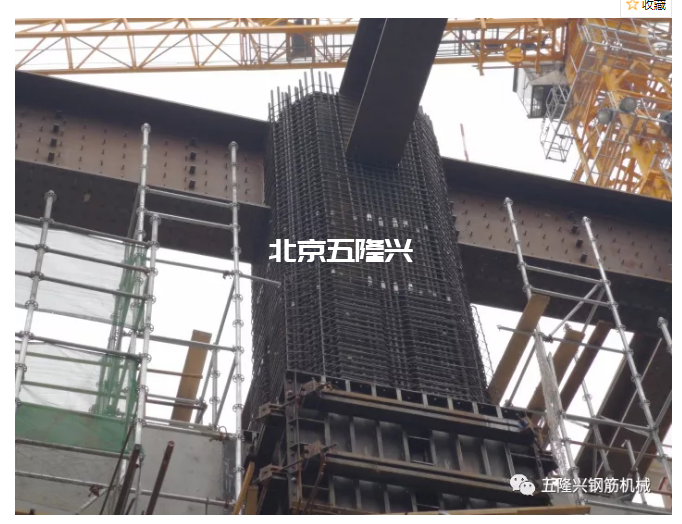

Figure 5: the vertical reinforcement is connected with the section steel beam. Similarly, the upper and lower reinforcement can complete the in-situ connection through the rotating sleeve when they cannot rotate.

Figure 6 perfect combination of straight thread and new sleeve, each application has its own advantages, reducing cost and increasing efficiency.

From the above data and cases, it is not difficult to see that the advantages of choosing double screw sleeve connection scheme in rigid column connection are clear at a glance!

五隆兴科技发展有限公司

五隆兴科技发展有限公司