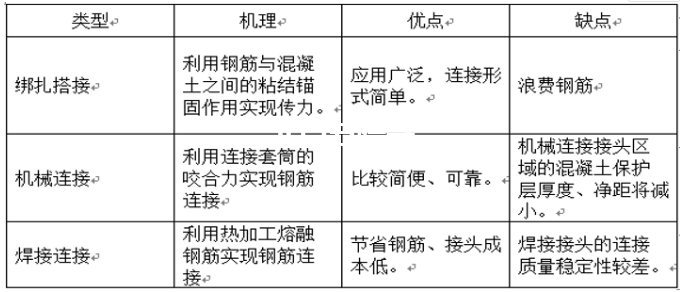

The reinforcement connection methods mainly include binding and overlapping, welding and mechanical connection. The characteristics of various connection methods are shown in the table below:

Rebar connection settings:

1. The joint shall be set at the place with small stress as far as possible, and the joint positions shall be staggered from each other. During seismic design, the scope of stirrup densification area at beam end and column end shall be avoided, and it shall be done in strict accordance with the requirements of atlas and specifications.

2. When the diameter of tensile reinforcement d > 28mm and the diameter of compression reinforcement d > 32mm, binding lap joint shall not be used.

The position of welding and mechanical connection joints is also very critical. Otherwise, it is found that they do not meet the requirements during acceptance, resulting in rework, which not only wastes human and material resources, but also affects the construction period. The acceptance points of the three connection modes are introduced below.

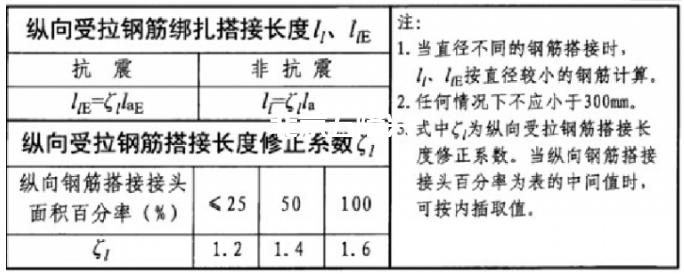

Binding and lapping

1. The binding and overlapping joints of adjacent longitudinal stressed reinforcement in the same member should be staggered from each other.

(1) The length of the same connection section is 1.3 times of the lap length ll, and all lap joints with the midpoint of the lap joint within the length of the connection section belong to the same connection section.

(2) In the same connection section, the percentage of overlapping joint area of longitudinal reinforcement is the ratio of the cross-sectional area of longitudinal stressed reinforcement with overlapping joint in this section to the cross-sectional area of all longitudinal stressed reinforcement. In the same connection section, the area percentage of lap joint of longitudinal tensile reinforcement shall meet the design requirements.

(3) When overlapping thick and fine reinforcement, the percentage of joint area shall be calculated according to the cross-sectional area of thick reinforcement, and the overlapping length shall be calculated according to the diameter of fine reinforcement.

Mechanical connection

1. The steel wire head of mechanical connection shall be processed before steel bar connection. The following points shall be paid attention to during the processing of reinforcement wire head:

(1) The construction personnel processing the rolled straight thread joint must receive technical training, and can work with certificates only after the examination.

(2) The reinforcement shall be straightened before processing. The end face of the notch shall be perpendicular to the reinforcement axis. If the broken end is bent, the horseshoe phenomenon shall be cut off, and gas cutting shall not be used for blanking.

2. Precautions for mechanical connection joint position of reinforcement:

(1) The joint of reinforcement should be set at the place with less stress. Two or more joints shall not be set for the same longitudinal stressed reinforcement.

(2) Joints in the same component should be staggered from each other.

3. Precautions for construction site inspection and acceptance of joints:

(1) The concrete protective layer of reinforcement connectors shall be made according to the design requirements. If there is no clear requirement, it shall be made according to the specification requirements (article 8.2.1 of code for design of concrete structures in 2010).

(2) When connecting reinforcement, the specification of reinforcement and sleeve must be consistent, and the screw threads of reinforcement and sleeve shall be clean and intact.

(3) When embedded joints are used, the position, specification and quantity of connecting sleeves shall meet the design requirements. The reinforcement with connecting sleeve shall be fixed firmly, and the exposed end of the connecting sleeve shall be provided with protective cover

五隆兴科技发展有限公司

五隆兴科技发展有限公司