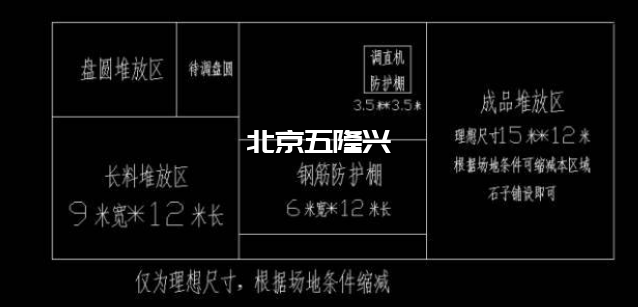

Setting principle and site requirements

The ideal site size of the reinforcement processing area is 36 meters long and 15 meters wide (which can be reduced according to the site conditions). It is divided into raw material area, processing area and finished product stacking area, and three areas are set according to the production line. The convenience and efficiency of reinforcement processing shall be considered in the placement position of mechanical equipment. Among them, the raw material area and the processing area are provided with concrete hardening (the column of the protective shed in the processing area also needs to be provided with an independent foundation), and the finished product stacking area adopts the method of stone laying hardening (cost saving, reasonable use of stone laying hardening instead of concrete hardening, in line with the principle of green construction)

Setting of raw material stacking area

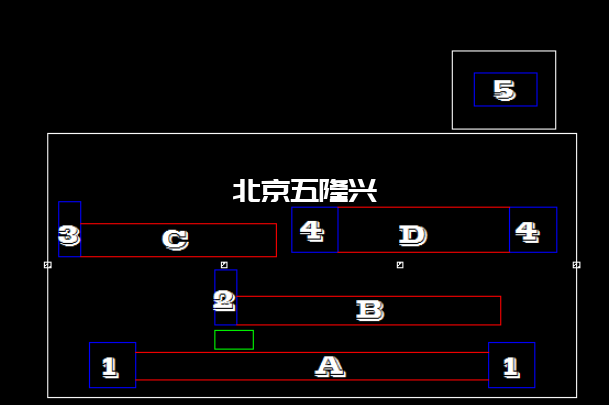

The materials stacked in the raw material area are long reinforcement (12m long specification) and coil. Separate strip foundation shall be set for long material reinforcement. The traditional method is to lay bricks, touch mortar and lay stones below, resulting in waste of artificial materials and inconsistent with the principle of green construction. The long material stacking area is set according to the following figure:

The distance between the front and rear rows is 2m, and a total of 4 rows are set, totaling 8m. The front and rear ends of the long material are 2m away (above)

The distance between the front and rear rows is 3M. There are 3 rows in total, with a total of 9m. The front and rear ends of the long material protrude 1.5m (as shown in the figure below)

Processing area setting

The practices of reinforcement protection sheds in various projects and units are inconsistent, but the single column method in the above figure is the most reasonable and fully utilized method.

Due to different models, brands and sizes of various equipment, the above figure is only a schematic diagram of relative position, which can be adjusted on site during on-site layout. The size of reinforcement protection shed (white line) is 6m * 12M, and the size of straightener protection shed is 3.5m * 3.5m.

Due to different models, brands and sizes of various equipment, the above figure is only a schematic diagram of relative position, which can be adjusted on site during on-site layout. The size of reinforcement protection shed (white line) is 6m * 12M, and the size of straightener protection shed is 3.5m * 3.5m.

Finished product stacking area

(2) The finished product stacking area can be directly hardened by laying stones or steel plates and precast blocks without pouring concrete.

(3) The finished product stacking area shall pay attention to the separation of long materials and stirrups and centralized stacking by category.

Many people say that my site does not have the above size conditions and there is not enough space. Although the layout we mentioned above is ideal, if we do not understand the matching principle of layout in these ideal states, we will not be flexible when the site conditions change.

五隆兴科技发展有限公司

五隆兴科技发展有限公司